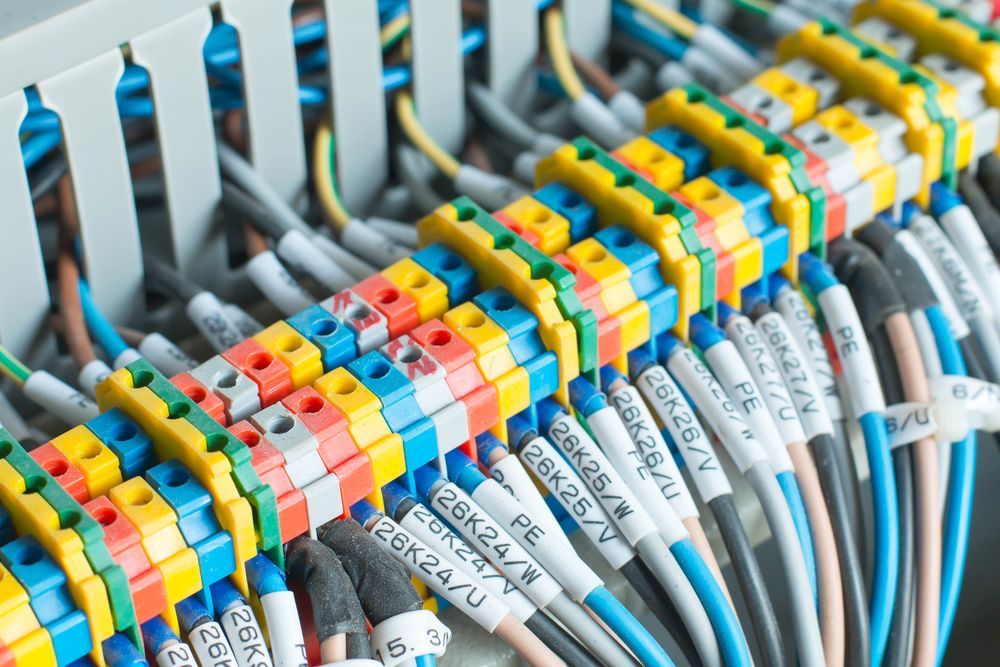

Wire Processing

High-Performance Precision Wire Processing

Kato Cable delivers precision wire processing services designed for performance-critical applications. Our team uses state-of-the-art automation and tooling to cut, strip, crimp, and terminate wires to exact specifications. Whether you're scaling production or need a custom solution, we maintain tight tolerances and repeatable quality throughout every project.

Every wire we process goes through rigorous quality checks to ensure it meets strict performance standards. Our focus on accuracy and repeatability helps reduce variability, minimize waste, and improve electrical connectivity across a wide range of OEM applications.

Wire Processing Solutions

Cut Strip Swing Arm

(Cut Strip Terminate):

Precision at every step. Our Cut Strip Swing Arm service combines cutting, stripping, and terminating wires in a streamlined process, ensuring accurate, high-quality connections for your projects.

Fully Automated

(Cut Strip Terminate/Bundle):

Efficiency at scale. This fully automated service performs cutting, stripping, terminating, and bundling in one seamless operation, increasing throughput while maintaining precision and consistency across large orders.

Twisting

(Up to 4 Wires)

Secure and reliable connections. Our twisting service allows for up to 4 wires to be twisted together, ensuring a robust and organized solution for applications requiring multi-wire assemblies with minimal space.

Benefits of Our Wire Processing Services

Our wire processing services are engineered to support production efficiency, reduce operational risk, and improve overall product integrity. With an emphasis on precision and process control, Kato Cable helps OEMs meet high-performance demands while staying on schedule and within budget.

Key benefits include:

Agile Production Support: Easily accommodate shifting order volumes and build schedules.

Lean Manufacturing Alignment: Dependable delivery and consistent output minimize inventory overhead.

Lower Error Rates: Advanced automation and in-line quality checks help eliminate costly rework.

Full Traceability: Detailed process documentation and part tracking provide accountability and compliance.

Streamlined Integration: Our services are built to plug into your manufacturing workflow with minimal disruption.

Process Control & Engineering Control Services

Process Control

Precision and consistency are at the heart of every custom cable solution. Our Process Control strategies ensure each assembly meets exact specifications, from initial concept to final production. Through rigorous quality checks, standardized procedures, and real-time monitoring, we optimize efficiency while maintaining the highest level of reliability.

Engineering Control

From concept to completion, Engineering Control ensures every design is optimized for functionality, manufacturability, and long-term performance. Our expert team evaluates form, fit, and function, applies industry best practices and testing protocols, and leverages innovative solutions to deliver high-quality and cost-effective cable and harness assemblies.

Our Products are Proudly Made in the USA

The Kato Cable Advantage

The Kato Cable Advantage is a holistic approach to looking at the value that you bring to your customers, employees and community. Our customers relate directly to our responsiveness and engineering value, to the investments that we have made into efficiencies and automation, and to the key metrics of industry leading Quality and On Time Delivery. Our employees relate to a sense of inclusion, an appreciation and value to feedback, and the philosophy of making improvements every day. Our community relates to our growth and volunteerism and leadership that we strive for in our region. Together these attributes and values truly deliver the Kato Cable Advantage!

Quality & Reliability

Delivering precision-engineered wire harnesses, cable assemblies, and electro-mechanical assemblies that meet the highest industry standards.

Innovation

Continuously improving processes and technologies to provide cutting-edge solutions for diverse industries.

Customer Commitment

Building strong partnerships through collaboration, responsiveness, and tailored solutions.

Applications & Industries We Serve

Our wire processing capabilities support manufacturers in complex environments where reliability and performance are critical. We deliver components built to meet exact requirements and withstand the demands of real-world applications.

Industries we serve include:

Automotive:

Supporting electric vehicles, heavy-duty trucks, and specialty builds with production-ready wire assemblies.

Industrial Equipment: Durable solutions for automation systems, controls, and rugged machinery.

Medical Devices: High-integrity processing for diagnostic, monitoring, and therapeutic equipment.

Power Generation:

Assemblies engineered to perform under high-voltage and extreme operating conditions.

Powersports & Recreational Vehicles: Compact, high-performance solutions for ATVs, UTVs, snowmobiles, and marine applications.

Agricultural Equipment: Robust assemblies designed to endure field conditions and long service life.

Our Certifications

Stay Connected with our Blog

Wire Processing Contact Us

We will get back to you as soon as possible.

Oops, there was an error sending your message. Please try again later.

Looking for Support?

Whether you're launching a new product or scaling an existing program, Kato Cable is ready to support your wire processing needs. Our experienced team works closely with OEMs to deliver responsive service, consistent quality, and solutions tailored to your production goals.

Let’s start a conversation. Request a Quote to learn more about how we can support your next project.