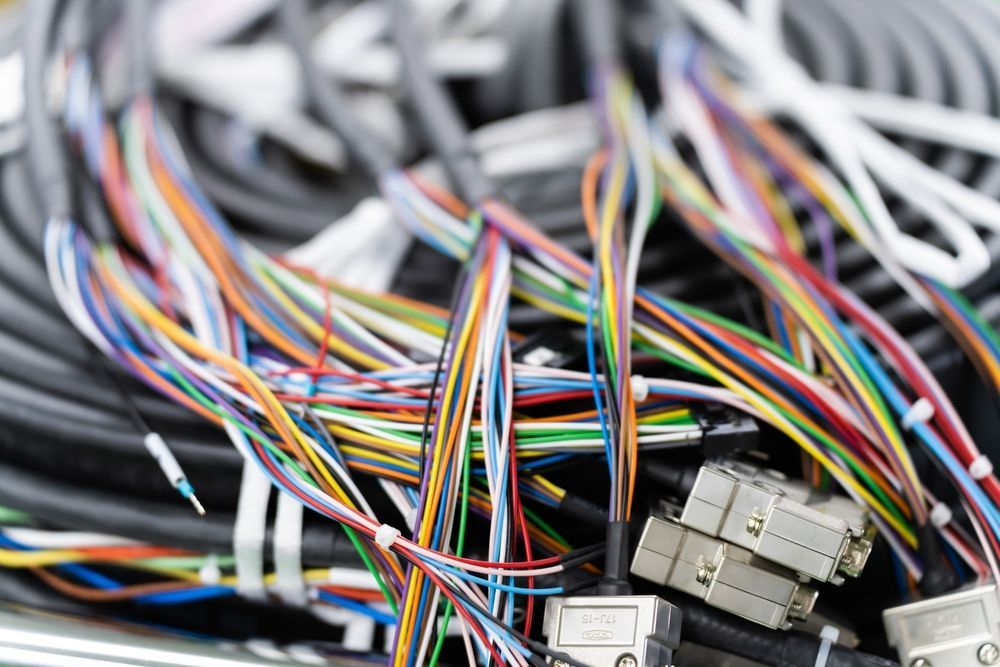

Agriculture Wiring Harnesses and Cable Assemblies

Powering Progress in Agriculture, One Wire at a Time!

Wire harnesses are a vital component for the agriculture industry, enabling the safe and efficient operation of machinery. As the industry evolves with new technology, wire harness designs will continue to adapt to meet the increasing demands of modern farming equipment.

Agriculture Wire Harness - How it Works

An industrial wire harness is a critical component used to organize and connect electrical systems in a wide range of industrial applications, from machinery to vehicles and automation systems.

What it is:

An industrial wire harness is an essential part of electrical systems that ensures the reliable, efficient, and organized distribution of power and signals throughout complex machines and equipment.

Function:

The harness ensures that electrical power and signals are transmitted efficiently throughout a system. It ensures correct connections between different components of machinery, including sensors, motors, and control systems.

Benefits

Durability and Resistance to Harsh Conditions:

Agricultural machinery operates in challenging environments such as dirt, moisture, and extreme temperatures. Agricultural wire harnesses are built to withstand these conditions and prevent electrical failures.

Vibration Resistance:

Agricultural equipment like tractors and harvesters experience constant vibrations. Wire harnesses designed for agriculture are built to absorb these vibrations, ensuring that electrical components remain secure and functional.

Safety and Protection:

With a well-organized wire harness, the risk of shorts, frays, or accidental damage to wires is minimized. This enhances the safety of operators and prevents fires or electrical hazards.

Improved Efficiency:

Wire harnesses ensure that the electrical connections in complex farming equipment are organized and efficient, reducing maintenance time and increasing operational efficiency.

Long-Lasting Performance:

These harnesses are designed to resist the corrosive effects of chemicals, fertilizers, and other agricultural materials that may be encountered during day-to-day operations.

Ease of Maintenance:

An organized wire harness system makes it easier to troubleshoot, repair, or replace components when needed, reducing downtime and maintenance costs.

Examples of Applications

Tractors and Combines:

Wire harnesses are essential for connecting the various electrical systems in tractors and combines, including engines, lights, sensors, GPS navigation, and hydraulic controls.

Irrigation Systems:

Automated irrigation systems use wire harnesses to connect controllers, sensors, and pumps, ensuring that the irrigation system operates efficiently and reliably.

Harvesting Equipment:

Harvesters utilize wire harnesses to control motors, hydraulic systems, and lighting, facilitating the harvesting process.

Plowing and Tilling Machinery:

Electrical systems in plows and tillers rely on wire harnesses for power control, safety lights, and monitoring systems.

Greenhouse Automation:

In greenhouses, wire harnesses are used for connecting automated systems for climate control, watering systems, lighting, and other sensors to ensure optimal plant growth.

Sprayers and Fertilizer Equipment:

Agricultural sprayers and fertilizer distribution equipment use wire harnesses to control spraying mechanisms, GPS tracking, and monitoring systems for efficiency and precision.

Process Control & Engineering Control Services

Process Control

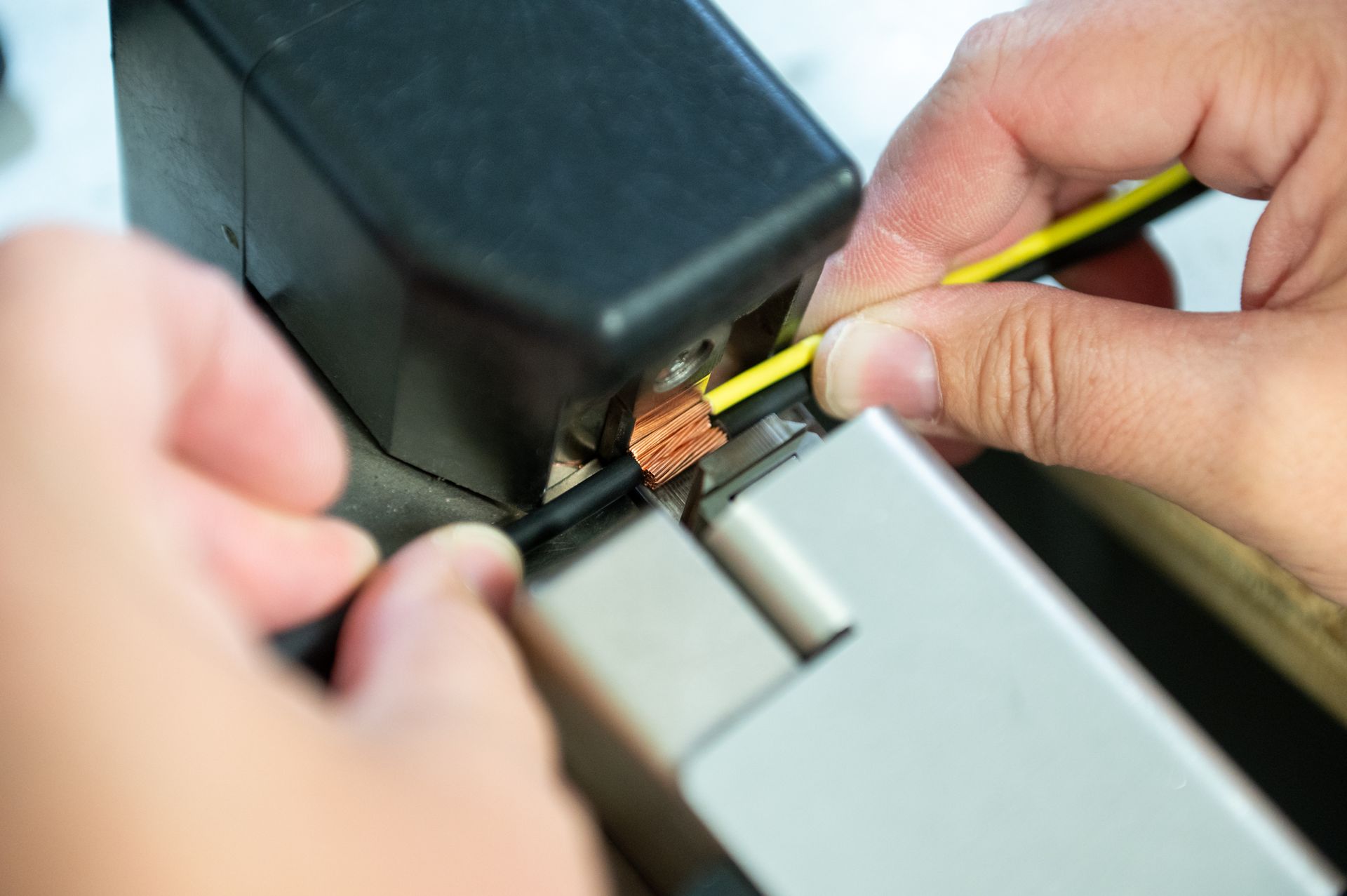

Precision and consistency are at the heart of every custom cable solution. Our Process Control strategies ensure each assembly meets exact specifications, from initial concept to final production. Through rigorous quality checks, standardized procedures, and real-time monitoring, we optimize efficiency while maintaining the highest level of reliability.

Engineering Control

From concept to completion, Engineering Control ensures every design is optimized for functionality, manufacturability, and long-term performance. Our expert team evaluates form, fit, and function, applies industry best practices and testing protocols, and leverages innovative solutions to deliver high-quality and cost-effective cable and harness assemblies.

Our Products are Proudly Made in the USA

The Kato Cable Advantage

The Kato Cable Advantage is a holistic approach to looking at the value that you bring to your customers, employees and community. Our customers relate directly to our responsiveness and engineering value, to the investments that we have made into efficiencies and automation, and to the key metrics of industry leading Quality and On Time Delivery. Our employees relate to a sense of inclusion, an appreciation and value to feedback, and the philosophy of making improvements every day. Our community relates to our growth and volunteerism and leadership that we strive for in our region. Together these attributes and values truly deliver the Kato Cable Advantage!

Quality & Reliability

Delivering precision-engineered wire harnesses, cable assemblies, and electro-mechanical assemblies that meet the highest industry standards.

Innovation

Continuously improving processes and technologies to provide cutting-edge solutions for diverse industries.

Customer Commitment

Building strong partnerships through collaboration, responsiveness, and tailored solutions.

Your Industry, Our Vision

Our Certifications

Stay Connected with our Blog

Agriculture Contact Us

We will get back to you as soon as possible.

Oops, there was an error sending your message. Please try again later.

Looking for Support?

Our team is here to help. Whether you’re looking for a custom solution or need support with an existing project, we’re just a message away. Reach out today, and let’s find the right solution for you.